Roll- and segment rolling machines for screws and particular threads

Roll-and segment rolling machines for screws and particular threads

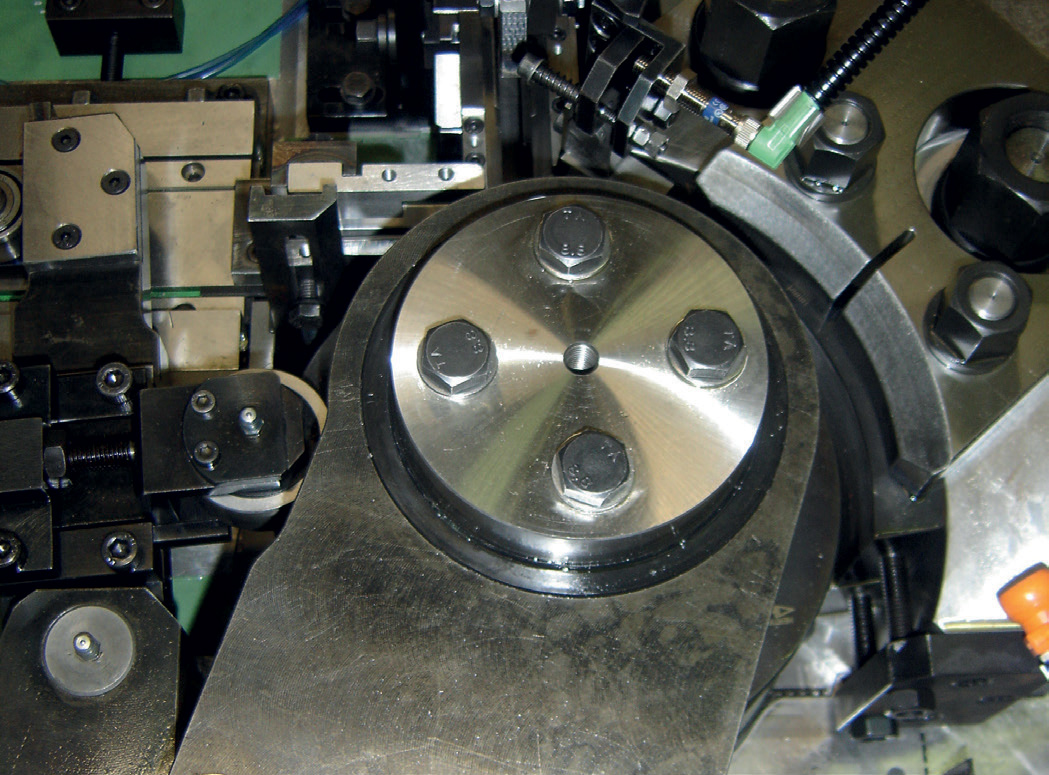

RS16

RS16

Rolling machines

Roller and segment rotary threading machines use different kinematics and fit different tools from flat die machines. To deform pieces, they use a central spindle, on which 1 threading roller and 1 segment are assembled on the tool holder. The screw to be threaded is fed between them by means of a feeder slide.

Technical features

Approximate values. The machine speed can change according to the material used and the type of item to be rolled. Measures in mm.

Output capacity

min 70 ÷ max 500

Screw diameter

min 6 ÷ max 16

Thread length

min 20 ÷ max 100

Max length of under head shank

150

Standard tool sizes

roll ∅ 127 sector ∅ 340

Total power of motors

HP 20

Approx net weight

Kg. 4000

Machine Sizes

2200x1000x1800